MIS Room R1A

The MIS 01 is a specialized workspace tailored for precision electronics assembly and rapid prototyping. This lab provides a dedicated environment where users can engage in delicate soldering operations, device assembly, and the fabrication of functional prototypes using state-of-the-art 3D printing technologies.

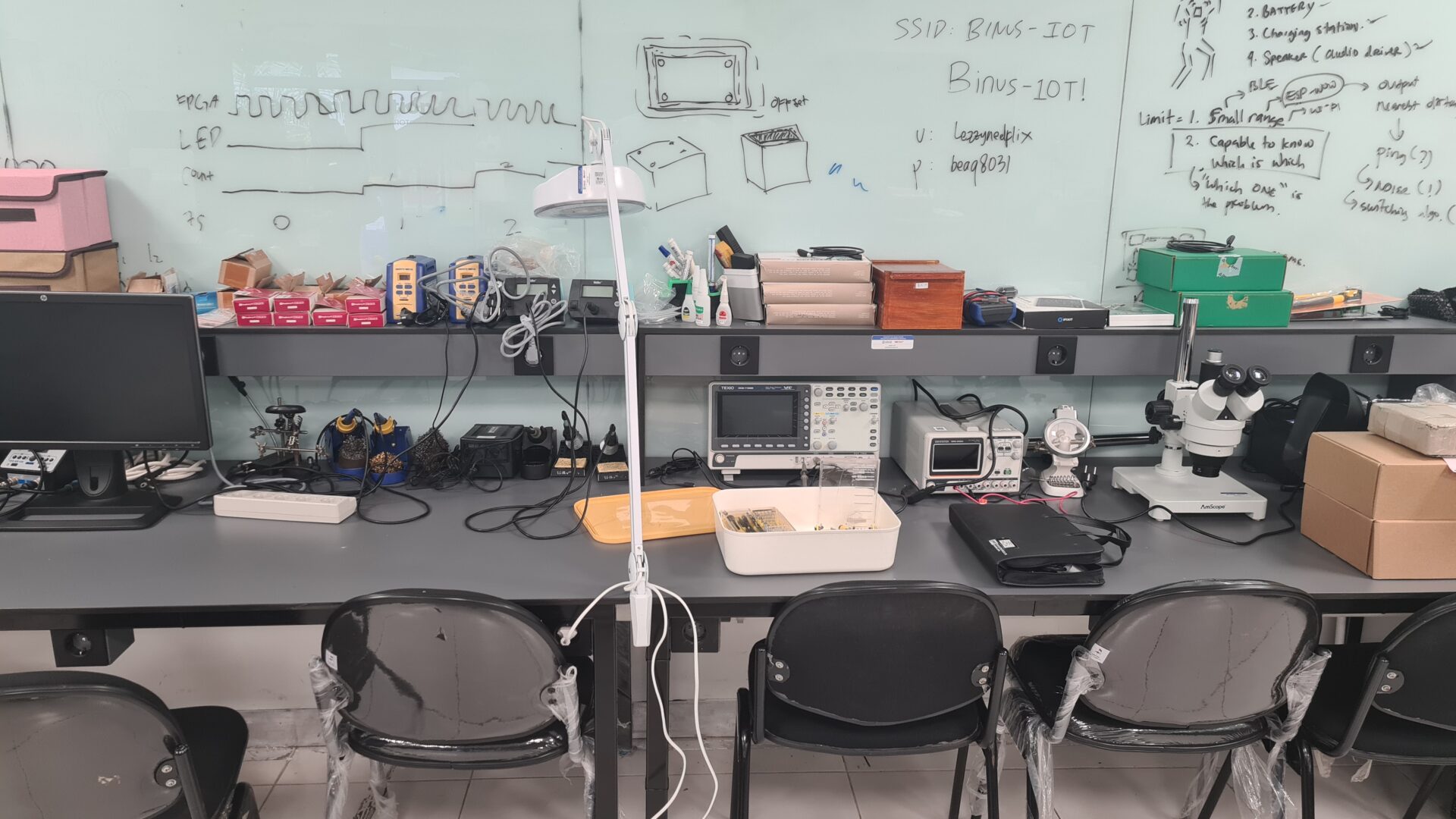

This section is equipped for both conventional soldering and advanced reflow soldering (hot air soldering). Individual soldering stations come complete with temperature-controlled soldering irons, hot air guns, fume extractors, and ESD (Electrostatic Discharge) protection to ensure safe and high-quality assembly of electronic components.

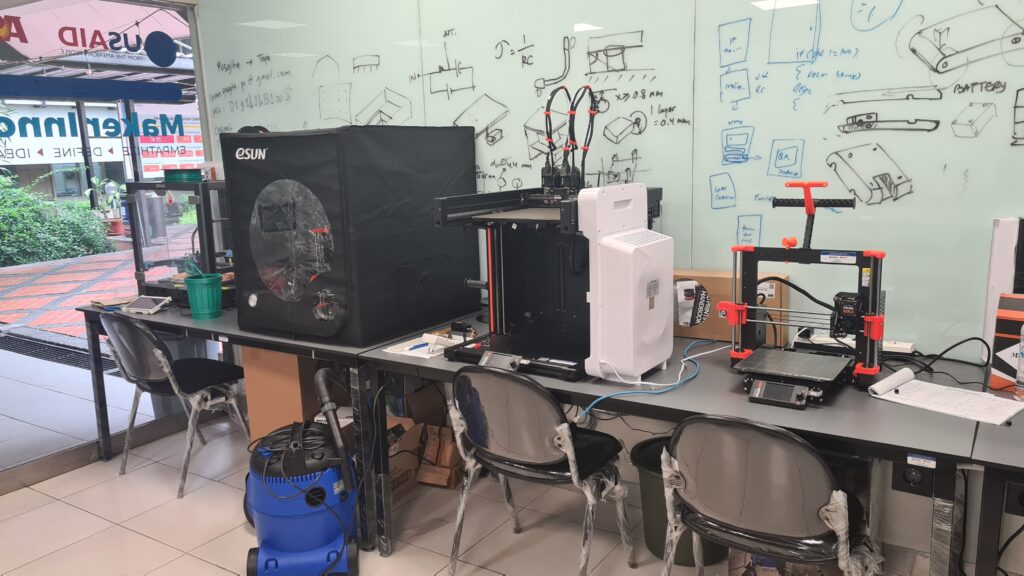

The prototyping area is fitted with multiple 3D printers capable of producing high-precision models in various materials. With designated post-processing areas for cleaning, curing, and finishing prints, users can rapidly iterate and bring their digital designs into tangible prototypes.

Displayed throughout the lab are selected works and award-winning prototypes created by students, highlighting their achievements in innovation, design, and national-level competitions. These showcases serve as a source of inspiration and motivation, encouraging a culture of excellence and creativity among lab users.

Prior to using any soldering or 3D printing equipment, users are required to complete a structured training program covering:

-

Safe soldering practices and equipment handling

-

3D printer operation, maintenance, and troubleshooting

-

Emergency procedures specific to electronics and printing operations

Certified staff members are present to supervise activities, provide technical assistance, and ensure that all operations are conducted safely and responsibly.

Comments :